Willkommen in der Welt für Christbaumschmuckvon Krebs Glas Lauscha

Jeder liebt Weihnachten. Zu dieser Jahreszeit genießen wir den großartigen Geruch von Lebkuchen und die Freude, Dinge an Menschen zu verschenken, die uns wichtig sind. Farbenfroher, klassischer oder besonderer Weihnachtsschmuck für jeden Christbaum oder gedeckten Tisch rundet das Weihnachtsfest ab.

Als einer der führenden Anbieter für exklusiven mundgeblasenen Glas-Christbaumschmuck in allen Farben und Formen bieten wir Ihnen erstklassige Qualität. Lassen Sie sich von der Vielfalt unserer Christbaumkugeln und dem besonderen Weihnachtsbaumschmuck verzaubern. Tauchen Sie ein in die Weihnachtswelt und holen Sie sich Ihre Lieblingsstücke nach Hause.

Als einer der führenden Anbieter für exklusiven mundgeblasenen Glas-Christbaumschmuck in allen Farben und Formen bieten wir Ihnen erstklassige Qualität. Lassen Sie sich von der Vielfalt unserer Christbaumkugeln und dem besonderen Weihnachtsbaumschmuck verzaubern. Tauchen Sie ein in die Weihnachtswelt und holen Sie sich Ihre Lieblingsstücke nach Hause.

Einblicke & Inspiration finden

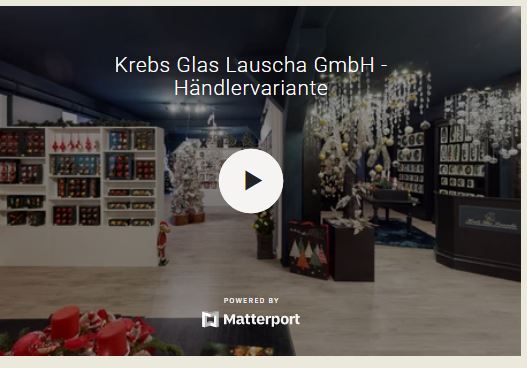

Unser Showroom in Lauscha

Detailansicht für verifizierte Händler unseres Showrooms in Lauscha. Lassen Sie sich verzaubern und inspirieren, auch wenn Sie nicht direkt vor Ort sein können. Gerne können Sie uns auch direkt in Lauscha besuchen und sich den Showroom live ansehen, bei uns bestellen und die Beratung vor Ort genießen.

Faszination Christbaumschmuck

Erlebniseinkauf in unserem Werksverkauf

Unser Werksverkauf befindet sich in Lauscha, dem Geburtsort der Glas-Christbaumkugel. Sie haben auf 350m2 mit über 5.000 verschiedenen Kugeln und Formen die größte Auswahl an Christbaumschmuck in Thüringen.

Des Weiteren befindet sich eine alte Arbeitsstube aus dem Jahr 1900 im Werksverkauf, bei der man eine Zeitreise zur Herstellung des Christbaumschmucks nach alter Tradition in die Vergangenheit machen kann.

Des Weiteren befindet sich eine alte Arbeitsstube aus dem Jahr 1900 im Werksverkauf, bei der man eine Zeitreise zur Herstellung des Christbaumschmucks nach alter Tradition in die Vergangenheit machen kann.

Immer einen Besuch Wert

Unser Werksverkauf in Lauscha

Sie suchen ein Weihnachtsgeschenk für Sie, Ihre Familie oder Bekannte? Unsere einzigartige Weihnachtswelt bietet für jeden Geschmack genau das Richtige. Schauen Sie einfach in unserer Christbaumschmuck-Welt vorbei.

Weitere Informationen zur Anfahrt finden Sie hier: HIER!

Alle Informationen zu unseren Öffnungszeiten finden Sie hier: HIER!

Weitere Informationen zur Anfahrt finden Sie hier: HIER!

Alle Informationen zu unseren Öffnungszeiten finden Sie hier: HIER!

Brigitte Hess

Local Guide

Berolina 101

Local Guide

Silvana Müller-Schwefel

Local Guide

Yully

Local Guide

dubler

Local Guide